The history of mesh is more interesting than you might think

Paul Smith of F.H. Brundle charts the history of one of the most versatile and widely-used products in our industry.

I’m willing to bet you haven’t spent a lot of time thinking about the history of mesh.

It’s unlikely to strike you or virtually anyone as an especially interesting topic. In fact, it might seem like one of those things that’s just always existed.

But, like every product, it has an origin – and only exists today because of the drive and determination of passionate inventors and entrepreneurs.

Where did the mesh journey begin? In America, at the very end of the nineteenth century.

Throughout the 1800s, the Industrial Revolution had radically reshaped the way millions of people lived and worked.

It upended traditional ways of building and manufacturing things, and the world of wood, horsepower and tiny cottage industries was replaced with huge factories and mass-produced iron and steel.

But it wasn’t until 1889, in Worcester, Massachusetts, that someone thought to patent a machine that could weld that steel into a wire panel.

Born in the USA

Think ‘metal’, and your first thought is likely to be of its most impressive, heavy-duty applications – industrial machinery, high-rise buildings, even battleship hulls.

But inventor John Perry could see it had huge potential to be used in other ways. By turning it into thin wires, he could make extremely versatile steel fencing, suitable for all sorts of industrial, agricultural and domestic settings.

Wire mesh has gone on to become immensely popular all around the world – it’s robust, cost-effective, and extremely quick and easy to install.

But unfortunately for John, at the time, the market wasn’t ready for his innovation. He secured the patent for his panel-making machine, but demand was limited, and he went on to use it for other purposes instead.

German innovations

The wire mesh gauntlet was later taken up in Germany by one Hans Lechtenbohmer – but again, there were challenges.

In the ‘50s and ‘60s, Hans began manufacturing his own mesh panels, but the installers of the time weren’t keen – his products were too costly, they said, and too heavy to easily install.

But Hans was undeterred. First, he set about installing his existing panels himself. Then, later, he developed a new design to counter the complaints he’d received from installers, making panels that were lighter and more competitively priced.

Hans wouldn’t go on to market his new and improved panel himself, however. The product, which consisted of a single panel reinforced with a V-shaped profile, risked competing with some of his other offerings – so he gave the license to another manufacturer instead.

By the 1990s, mesh use was widespread – and the material was prized above all for its versatility. It could certainly provide viable obstacles to help protect public buildings or private premises.

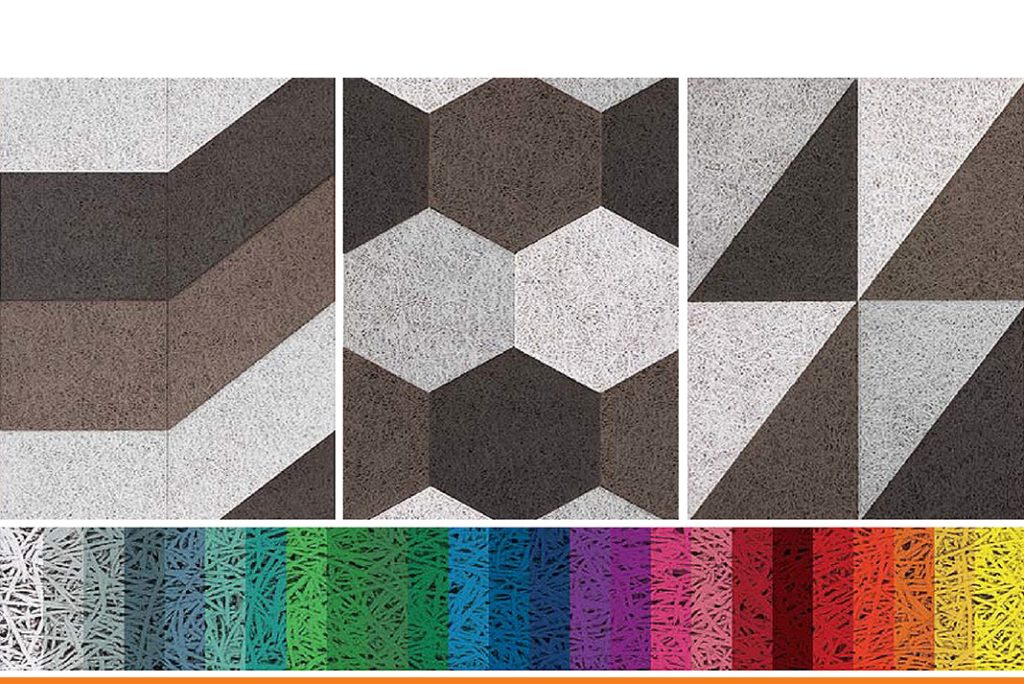

It was also widely utilised in construction, civil engineering and transportation, and for architectural applications like walkways, balustrade infill panels, cladding or gabion baskets.

But it was also suitable for more creative applications. It could be used to protect walls and other more solid structures from graffiti. It could act as trelliswork for growing vines and hedges – and it could even be finished in a company’s corporate colours for branding purposes.

Still versatile after 120 years

In the decades since, the use of wire mesh has increased rapidly around the world, as has the variety of mesh products that are now available.

Today, at F.H. Brundle, we’re the UK’s leading welded wire mesh suppliers, providing mesh products suitable for a huge array of domestic and industrial settings.

In workshops or factories, mesh can be used for window grilles or as machinery guards, for example, while in warehouses, it can be used for racking, storing and as anti-collapse mesh.

Homeowners can use it in their gardens for plants and creepers, or to make animal enclosures for birds, rabbits and dogs. In farming, feed racking systems, rearing cages and more are often built with welded mesh.

With a range encompassing light welded wire mesh rolls, heavy industrial wire mesh panels, self-colour mesh wire, 304 grade stainless steel welded mesh, 316 grade stainless steel welded mesh, and PVC welded mesh and now even black PPC, we’re confident we can meet virtually any wire mesh requirement.

In addition, we supply reinforcing wire mesh and wire fabric for concrete, as well as a range of mesh clips, and provide a welded mesh ‘cut to size service’.

120 years since it was first invented, mesh is as useful as ever – and if you want an excellent range of it, backed up with first-class service, speak to F.H. Brundle today.

Call 01708 253545 or visit www.fhbrundle.co.uk.