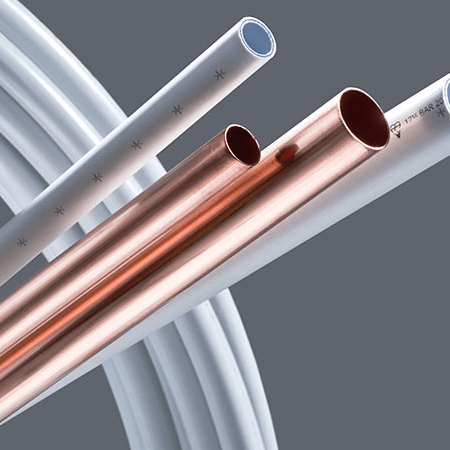

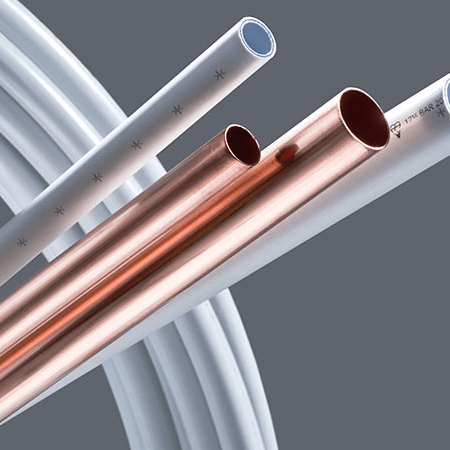

Plastic or copper pipe? There is a correct answer

Deciding whether to use plastic or copper pipe, is one of the first things that an installer considers when tackling a plumbing project. However, regardless of the choice the installer inevitably makes, there will be others ready to sing the praises of the other system. Whilst each has its own applications, and it is best to be well-versed in both, recent technological developments have made it clear that plastic plumbing systems are progressing much faster than their copper counterparts. By taking a more in-depth look at the benefits in this blog, RWC hope to make it easier for you to decide whether plastic or copper pipe is the most appropriate system for your project.

Explaining what plastic plumbing is

The first thing to note is that plastic, in this case, means PEX plastic and polybutylene plastic, which despite both being a kind of polyethylene, have some differences. For example, polybutylene is a much more flexible material than PEX, due to there being less memory in the coil. Additionally, PEX is a crosslinked plastic and can therefore tolerate higher water pressures than polybutylene.

While the two plastics largely serve the exact same purpose, it is still best practice to be aware of which of the two materials you are working with when using plastic pipe.

Does plastic plumbing perform better than copper?

Copper pipe certainly has its die-hard fans, and it’s easy to see why. Copper pipes and fittings have multiple performance benefits, most notably the fact that they are biostatic. This means that they have anti-microbial qualities that don’t allow for the growth or multiplication of any organism, but most importantly micro-organisms such as bacteria. This is the same reason that the bases of ships get coated in copper, to prevent the growth of organisms such as barnacles.

However, beyond this plastic plumbing systems have multiple performance benefits. For example, Plastic pipes can easily be demounted and reconnected with residual water in the pipe. Whereas the heat of soldering wet copper pipework causes steam in the pipework, which is also a danger to the installer.

A key benefit that JG Speedfit’s plastic pipes has over copper alternatives is a five-layer barrier system. This system insulates the water so that the expansion and contraction that happens as a result of natural temperature changes throughout the day, only affects the metal fittings attached to the pipe, not the pipe itself, which reduces any potential risk of air ingress into the system. equally, the minimal expansion and contraction of plastic systems reduces the noise that the system makes too.

Are plastic pipes easier to install than copper?

While there are certain situations where regulations dictate that copper pipe must be installed, in the majority of other situations many installers will turn to plastic fittings and pipes. And there’ll be no flirting around why either – it’s not much of a secret after all. Indeed, one of the main selling points of plastic plumbing systems is the ease of installation.

Plastic push-fit fittings, such as those in the JG Speedfit Twist & Lock® range, only require a pipe cutter to make a watertight connection. Whereas copper pipe needs to be fluxed and de-burred before soldering, and then cleaned after the fact too, meaning that plastic plumbing wins from an ease of installation perspective. Additionally, some places will require a hot work permit for using the tolls needed for copper pipe, this is easily circumvented by simply using plastic plumbing systems instead.

Are plastic pipes and fittings more durable than copper?

On paper, you would think that copper pipes and fittings would be far more durable than their plastic counterparts, metals are typically viewed as stronger materials after all. However, many would be surprised to learn both copper and plastic plumbing systems are advertised as having similar lifespans, this of course varies based on a number of factors, such as the type of water the system is receiving, the quality of the installation, and the amount of usage the system gets. However, these factors tend to affect copper systems more than plastic ones, as, for example, copper can oxidize or corrode when used with water and air, so it is more susceptible to damage or pitting, than its plastic counterpart.

Is plastic plumbing more affordable than copper?

Finally, another reason why many installers prefer plastic pipe over copper is the price point. Whilst copper plumbing doesn’t cost nearly as much as other metal plumbing systems, such as stainless steel, they are still far more expensive than plastic ones.

On an individual basis, plastic pipe costs less than copper pipe but typically copper fittings cost less than plastic fittings. However, many don’t consider the outside factors that negatively affect the copper price point.

Firstly, when using copper plumbing systems, you will have to expend extra money on consumables such as flux, gas, and solder, which is not a requirement when working with plastic plumbing systems. Similarly, plastic plumbing systems, as an easier-to-install system, save a lot of money on labour costs overall.

Plastic plumbing is progressing much faster than copper plumbing

Whilst regulations dictate that copper plumbing must be used in certain scenarios and indeed it possesses unique performance benefits, innovations in plastic plumbing are making it a much more well-rounded solution. Additionally, whilst it is common to see both systems being used in conjunction with one another, with copper pipe fitting into plastic fittings and vice versa, plastic plumbing looks to be the way forwards.